WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this month!

Engines and Accessories

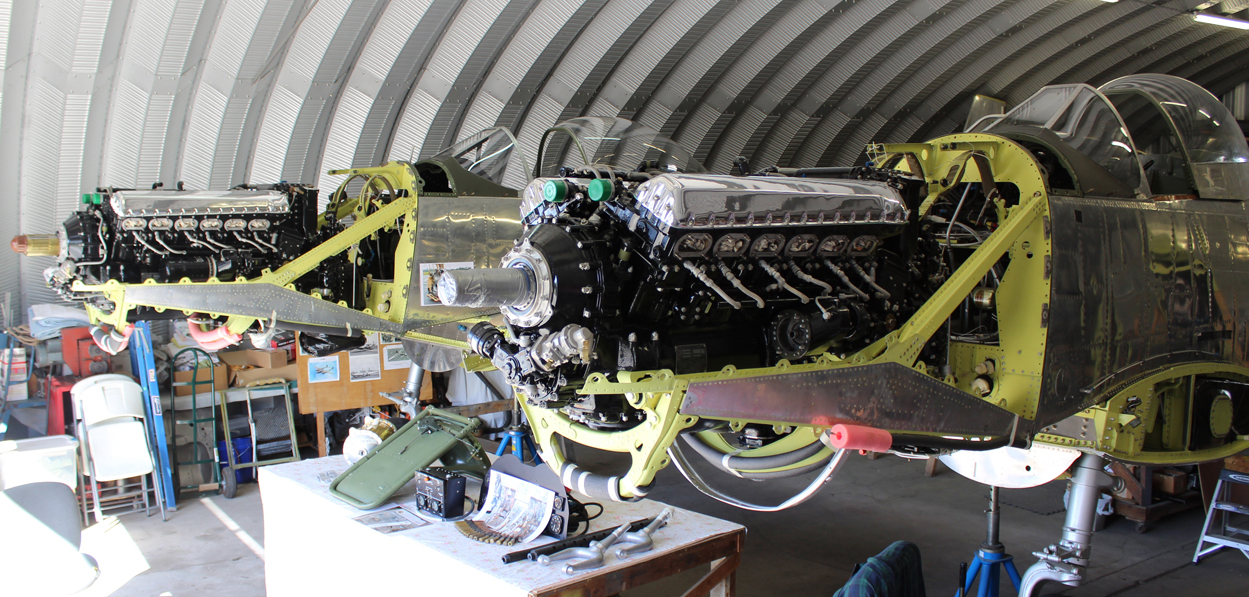

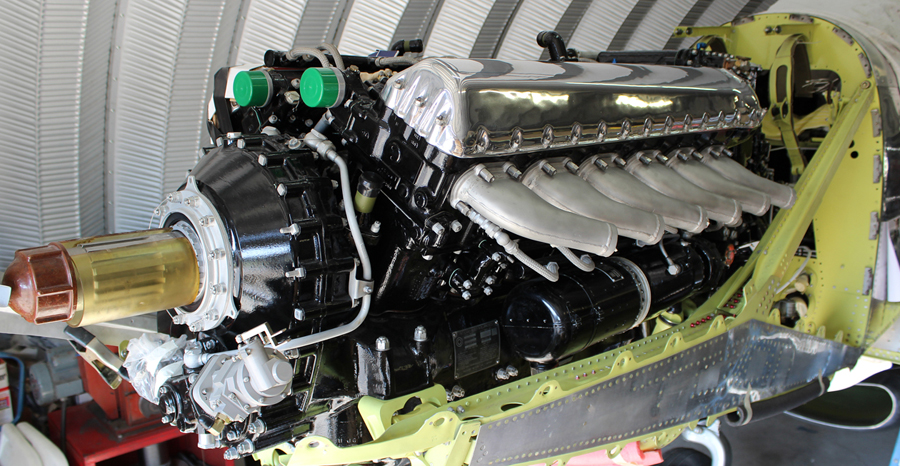

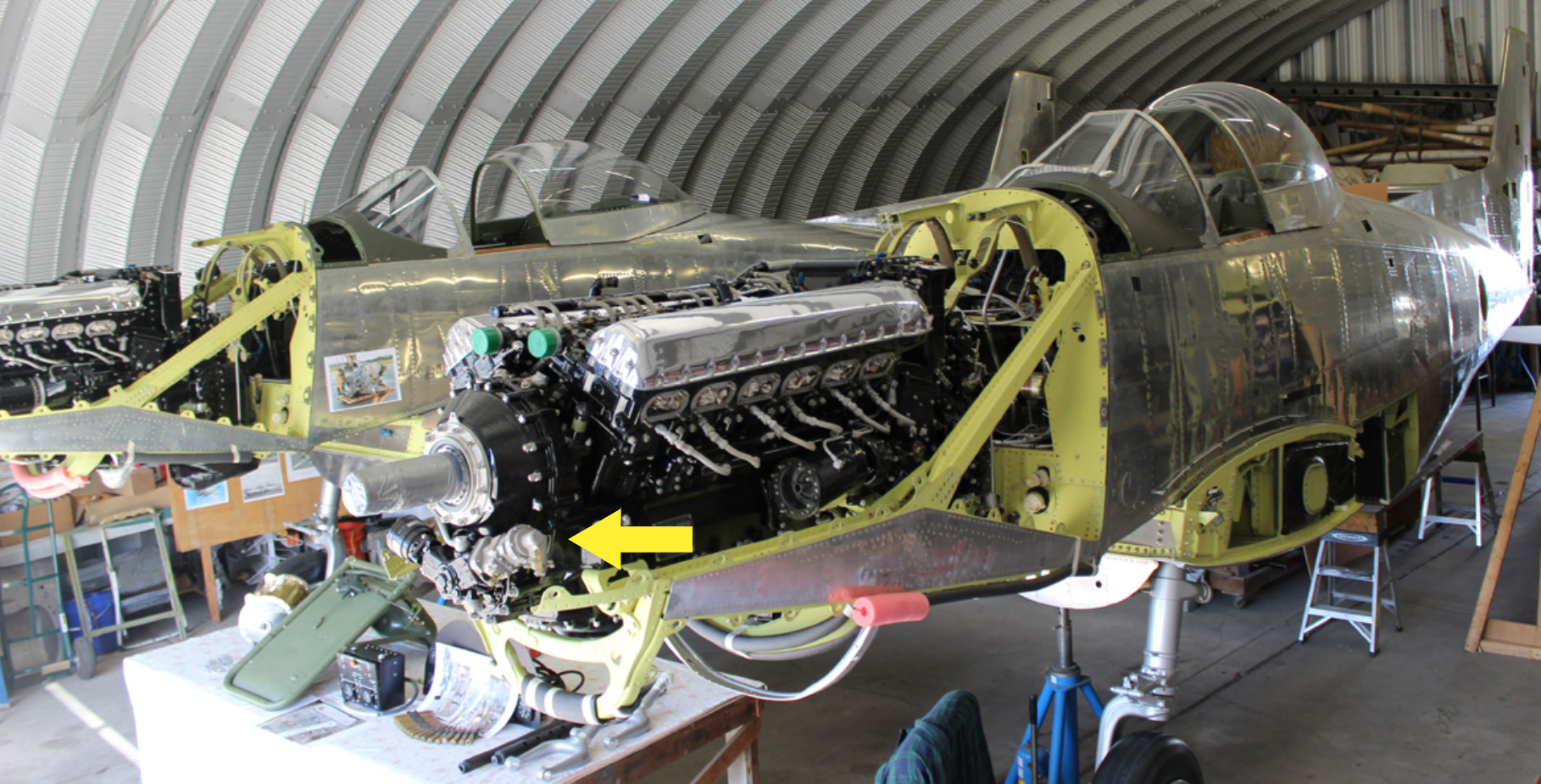

Both engines are now permanently installed with all of their overhauled accessories mounted, minus one vacuum pump and one generator. Both of these items should be at the shop and installed next week.

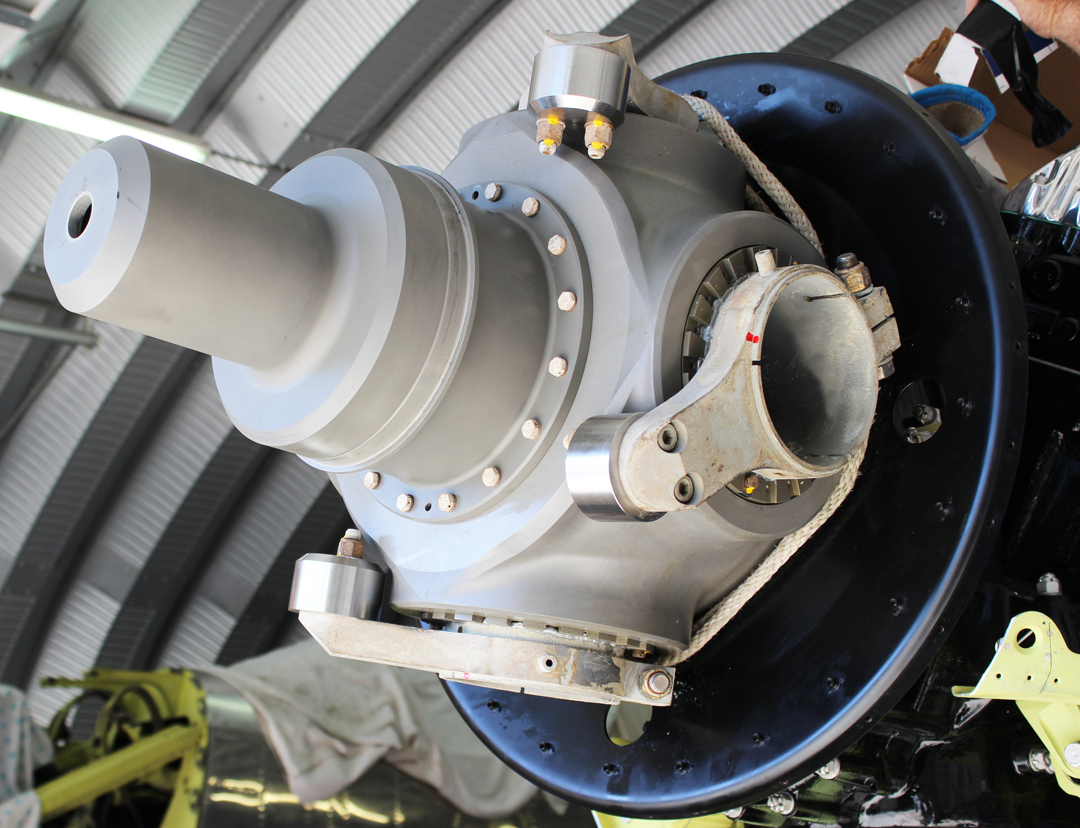

Also, both MT Propeller governors are installed. One MT Propeller hub and spinner backing plate has been test-fitted on the port engine prop shaft. It has a microscopic mechanical interference issue with a small governor screw and feather fitting which should be fixed easily with a little deeper countersink for the screw and fitting.

MT Propeller Blades (8) and Hubs (2)

Tom Reilly is making arrangements with MT Propeller in Germany for both propellers to be delivered to the company’s U.S. base of operations in DeLand, Florida. One of their German propeller technicians will assemble both four-bladed propeller units and Reilly will then haul them back to his shop in Douglas, Georgia on a factory-provided propeller trailer.

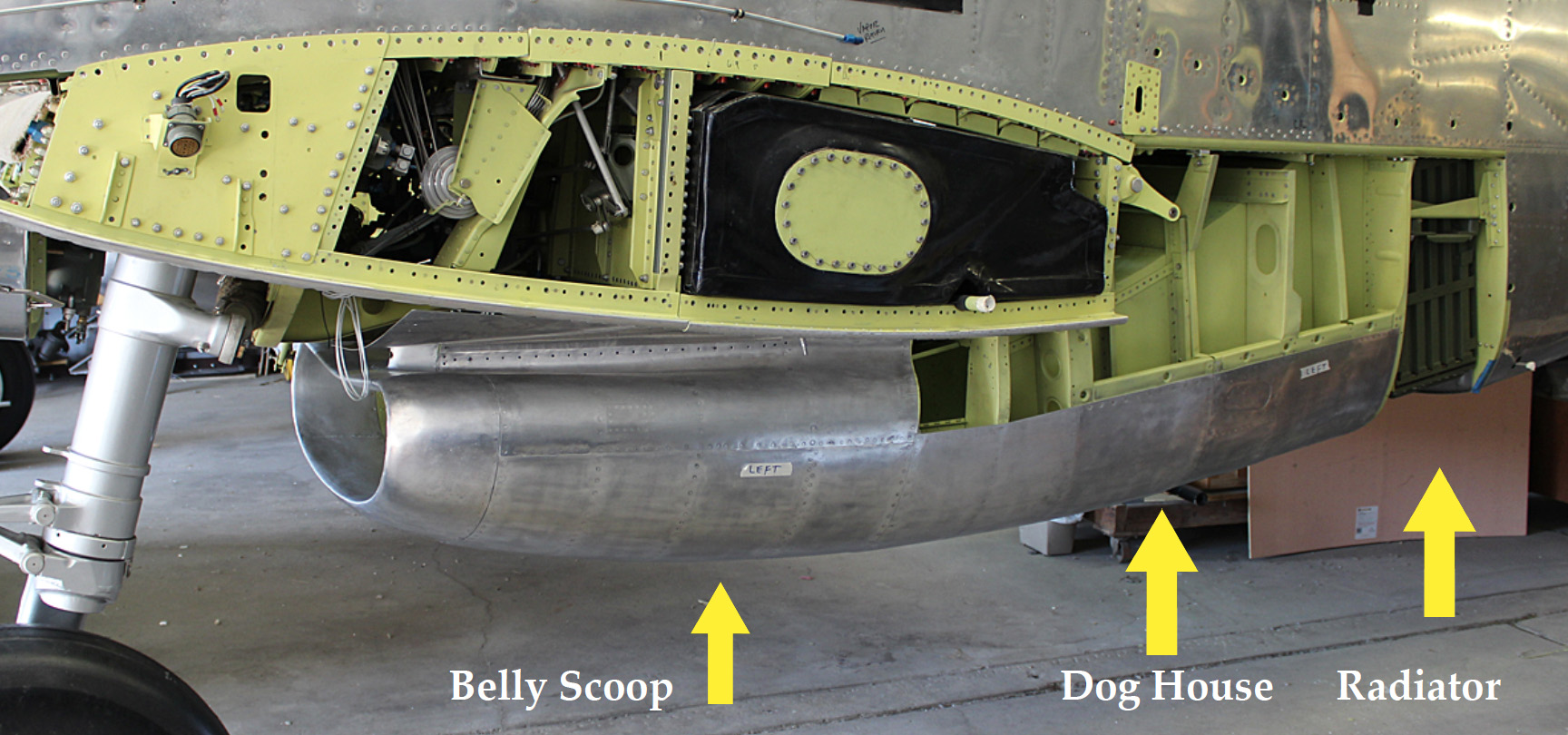

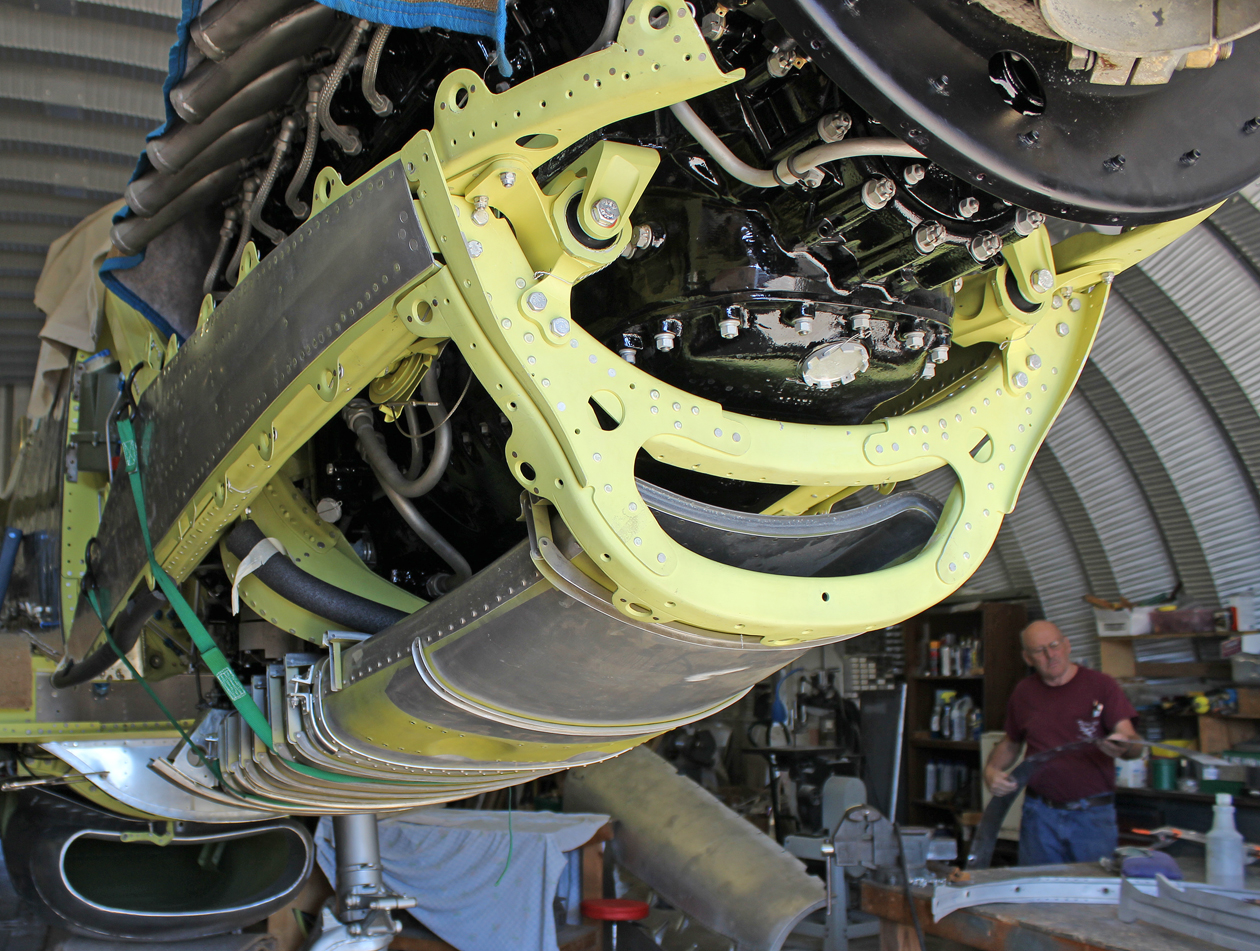

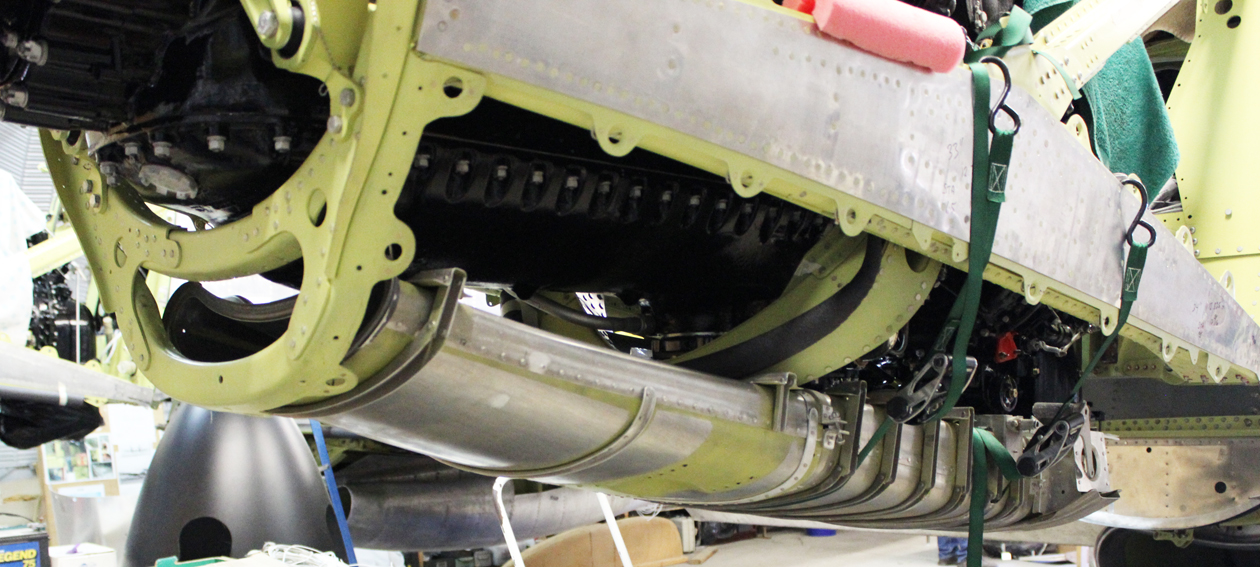

Belly Scoops, Dog Houses, Radiator Seal Frames & Induction Trunks

All of these components have been restored for some time now, and this past week the restoration team took them out of storage and test-fitted them on the aircraft. The process went smoothly with only a minor amount of trimming and alignment necessary.

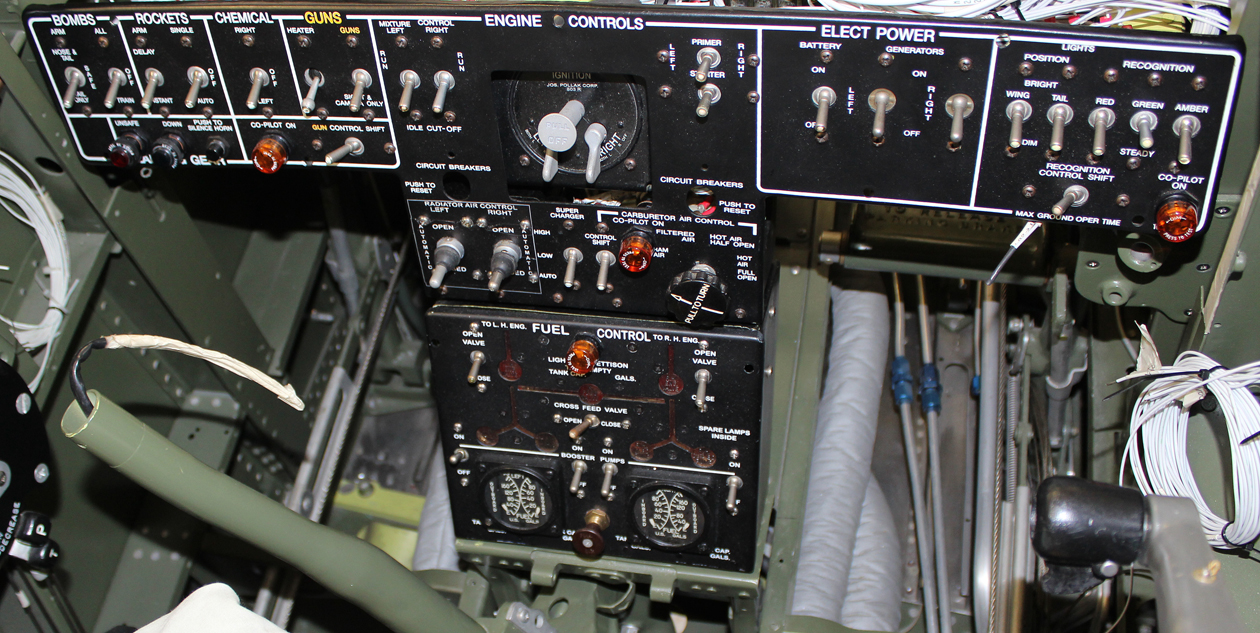

Guns & Ammo

Reilly spoke to the machine shop completing the XP-82’s .50 caliber replica guns and received assurance that they should be completed sometime in mid-November. A machine gun buyer/seller contacted Tom Reilly and told him that he will be bringing all of the loaded ammunition, heads and primers (less powder), sometime in December or January.

Cowlings – Firewall Forward

Three restoration team members have started to fit the cowling skins on all of the completed cowl ribs that they finished prior to their get together. The team is having some fitting difficulties with the new cowl skins that they had made four years ago. But with some additional English wheeling they should fit properly. Reilly is an expert on the English Wheel, a special roller machine used to form compound curved skins.

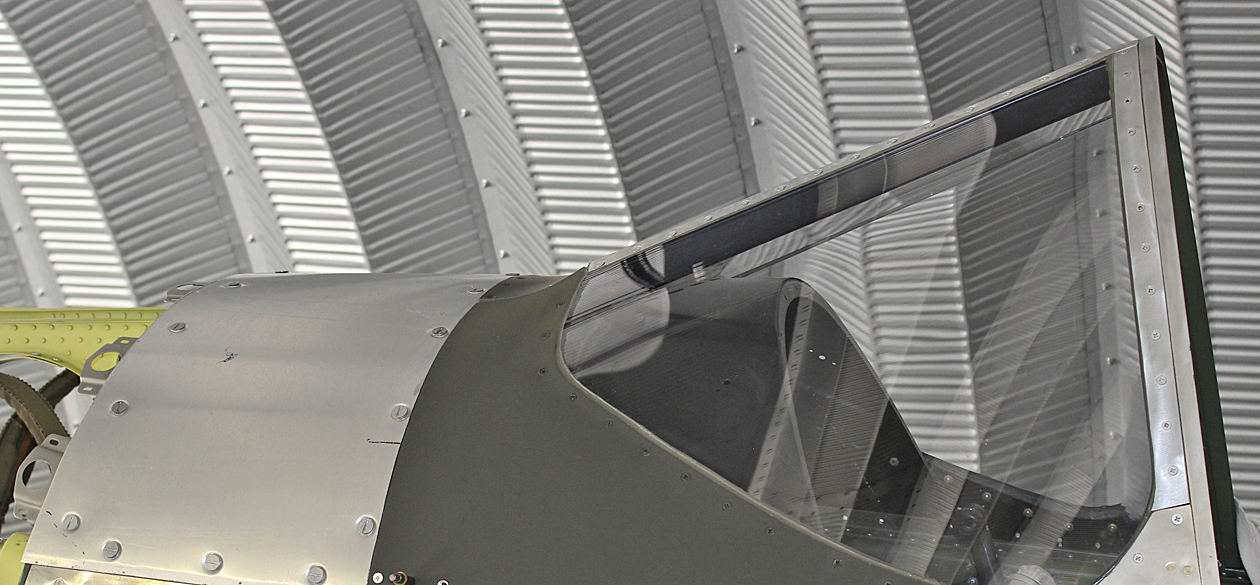

The forward windshield close-out panel in place. (photo via Tom Reilly)

As must now be clear to everyone, the XP-82 is really starting to take shape and look like an airplane again. Reilly says that the shipping containers are becoming more and more empty every day with all of the completed parts being installed on both fuselages.

Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in October for the next installment in the story following the XP-82′s road to recovery!

Can’t wait to see this Twin Mustang take to the skies!!

While admiring the photos, something was discerning in the engine compartment and I couldn’t figure what it was but then all of a sudden it hit me. Not literally but it just became apparent. The valve covers, I have never seen chromed or polished which ever covers on a Merlin before and am wondering if this is a personal effect or were they really shined up like that ? Would you enlighten me on this, please.

From the photos it appears Mr Reilly has a winner for sure.

Thanks

Terry