WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this past month!

First of all, the project is fully moved into their new hangar. A lot of progress has been taking place with the finishing touches on the aircraft too!

Firewall Forwards

The last left-hand engine upper, lower and side cowling items are now complete. The final installation of the left-hand propeller has also been completed, with the exception of the spinner. The spinner will remain off during the engine test runs to allow easier observation of any potential leaks.

According to Tom Reilly, the final mounting of the right-hand propeller should be complete by the time these words are read.

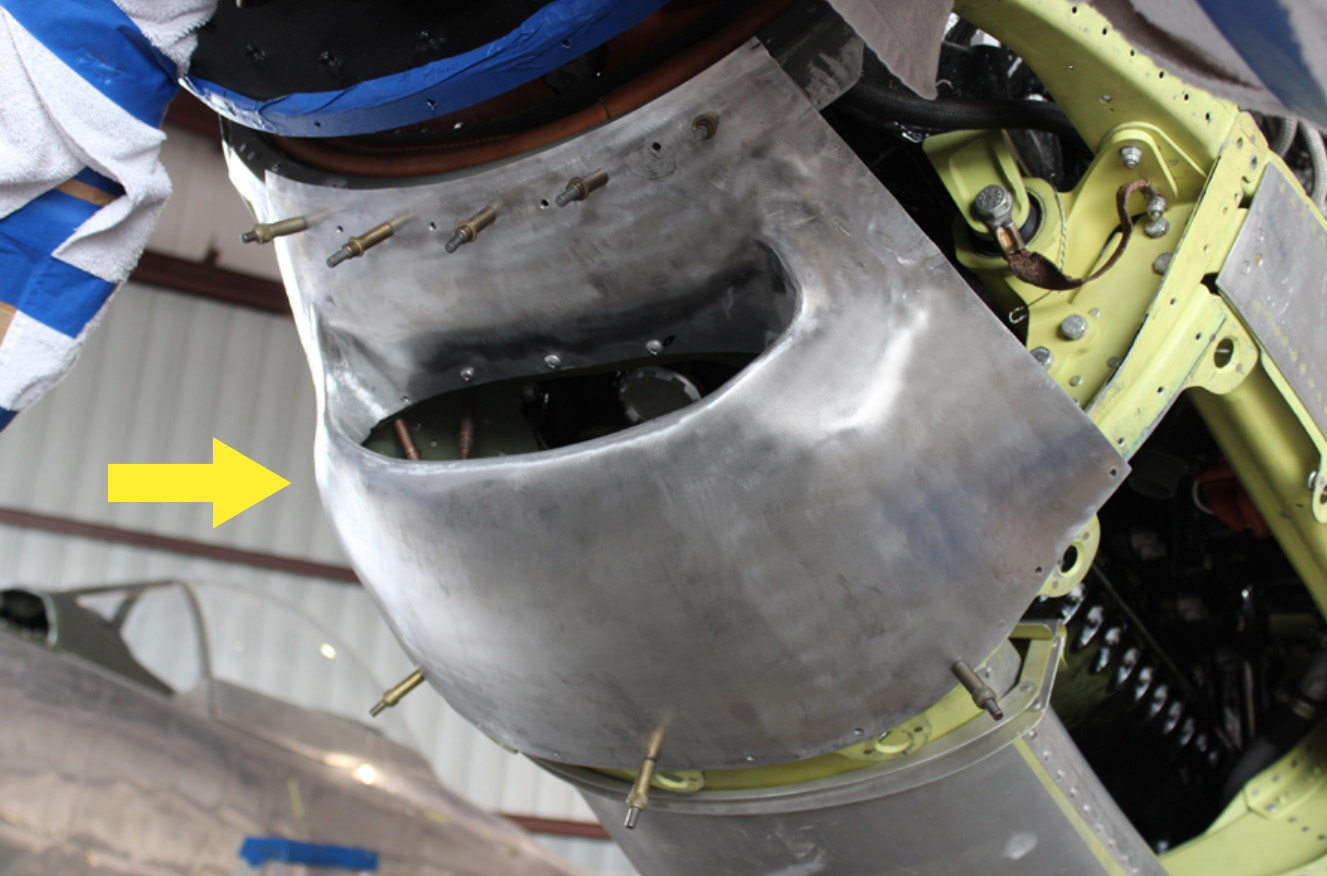

The induction-trunk lower intakes for the right-hand and left-hand engines have now been completed and are being final-fitted, awaiting sanding and polishing. These were very difficult forming tasks. The rotating carb air temperature barrel mechanisms and mounting structure are now also final-fitted, but presently removed to allow painting.

The mounting installation of both heat exchangers (oil/intercoolers) is now complete. These parts both presented a problem, as they interfered with the upper cowling arch framework. The project had the original exchanger mounting straps attached to the dishpans, but did not have the original rings that mounted the exchangers to the straps. When Reilly’s team machined the rings, as per the XP-82 drawings, the exchangers would mount about an inch higher and not nestle into the two factory-formed notches in the oil tanks. After redesigning and machining the four new mounting rings, the restoration team solved the interference problem.

Engines/Props

The test running of both engines and all of their associated systems will start this December.

Outboard Wings

The English wheel forming of the two wing tips is progressing rapidly. Both upper wing tip panels are finished and the two lowers are in production. Tom Reilly expects them to be completed sometime in mid-December.

Landing Gear/Doors

The subcontract machine work of the press dies for the inboard gear doors is progressing nicely. The outboard door skins have been ready for some time now, and are awaiting the completion of both interior frameworks.

Tail Wheel Steering

Both tail wheel steering mechanisms are now final-installed, less tensioning. A number of moving parts are required to turn the two tail wheels left and right.

Brakes

The machine shop is currently 3-D modeling both brake calipers. These brake assemblies fit only the XP-82 and subsequent Twin Mustang production models. They have a unique, anti-skid design and worked extremely well according to pilot reports.

Authentic Interior Cockpit Furnishings

The restoration is heavily involved with completing the internal parts for each cockpit: gun sights, gun camera, oxygen regulators, gauges and blinkers, original radio heads, heater and defrost controls, exterior ADF ring antennae, etc., etc.

VIP Visitor

The project had the honor of a visit from WWII Army Air Force veteran Col. Robert Thacker, now 98 years young. He is famous for piloting the P-82B named “Betty Jo” on its non-stop flight from Hawaii to LaGuardia Airport in New York on February 27th, 1947. Tom Reilly was amazed by how sharp and alert Col.Thacker is for such an advanced age. He still remembered every detail that went into the record-breaking flight’s preparation – the test flights, the additional fuel tanks installed inside the fuselages, and the exterior drop tanks … as well as why three of the four drop tanks could not be jettisoned (the sway braces were over-tightened by a ground crewman which prevented the release hooks from operating). One of the tanks did drop leaving the other three under the wings, creating a dramatic yaw condition which required a substantial amount of rudder trim drag.

Col. Thacker described, in detail, the additional 150-gallon fuel tanks installed behind each pilot seat and the 60-gallon tank installed in the gun bay. He even distinctly remembered a plug being inadvertently left in the gun bay tank vent line during one of the test flights, resulting in the tank collapsing and a replacement having to be manufactured.

The P-82 had a total of 1,860 gallons of fuel at lift off, including the 600 gallons of production center section and wing tanks, two 300 gallon and two 150 gallon wing drop tanks, and the 360 gallons of additional internal tanks added for the long flight.

Total distance from Hawaii to New York – 4,899 statute miles. 14.5 hours total flight time. Average cruise speed – 338 miles per hour. Taking tail winds into consideration, that’s 300+ mph cruise.

Tom Reilly hopes his own memory of the details Col.Thacker related during his visit three weeks ago is as good as his memory at 98 years young!

Concorde Battery

Tom Reilly also wished to offer special thanks to Mr. Don Grunke of Concorde Battery Corporation. Concorde contributed a brand new battery for the XP-82 project. The quality of their batteries is outstanding, according to Reilly, with one of their units lasting nine years in his B-25 Mitchell!

And that’s all of the news for November, 2016!

———————————-

Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in January, 2017 for the next installment in the story following the XP-82′s road to recovery!

Be the first to comment

Graphic Design, Branding and Aviation Art