As usual, WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia. Here’s what they’ve been up to this month! October saw some major milestones achieved in the XP-82 restoration!

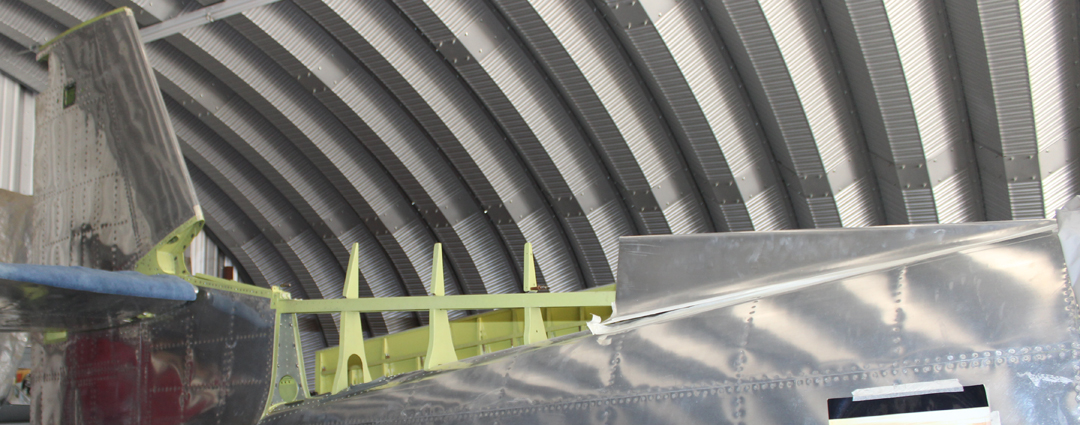

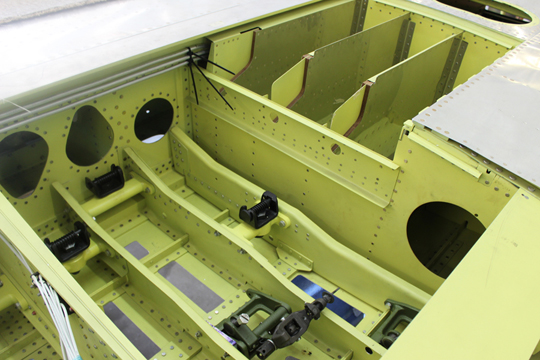

Aft Fuselage Extensions/Dorsal Fins

The final microscopic alignments and attachment of the aft fuselage extensions are complete, along with all of the primary and secondary flight control pulley brackets, many phenolic cable guides and the tail wheel attachments. The team is now into fitting the two dorsal fins on the top of the aft fuselages where they flare into the vertical stabilizers.

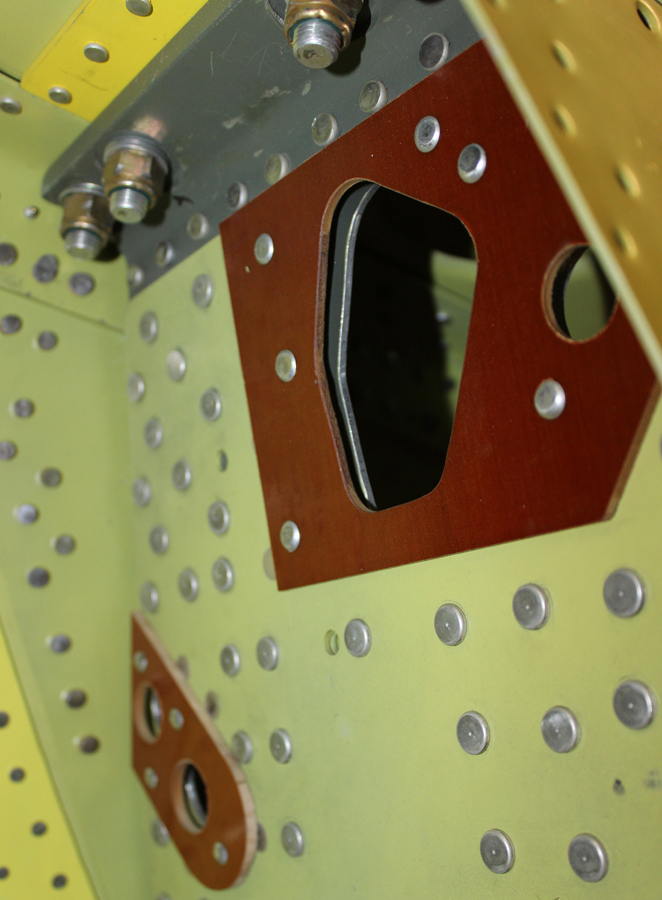

Canopies and Windshields

Both canopies are now permanently fit and attached. The canopy jettison systems are fully adjusted so that all three releases on each canopy release simultaneously. Both windshield frames and glare shields are now trimmed and permanently fitted, and await the four windshield side glasses. A second team is also attaching the fairings that fit underneath the aft section of both canopies. These fairings seal the canopies to the fuselages as the canopies roll forward.

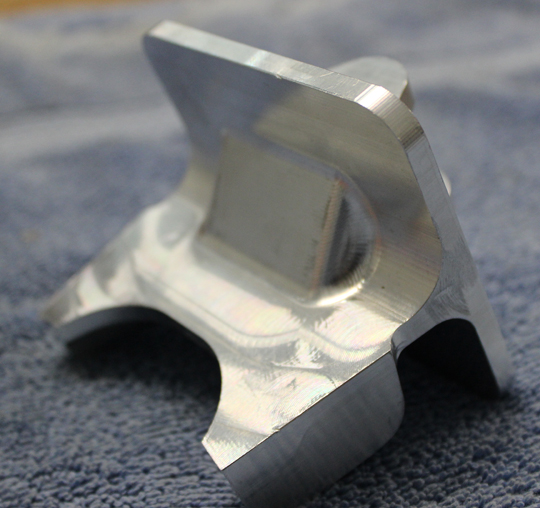

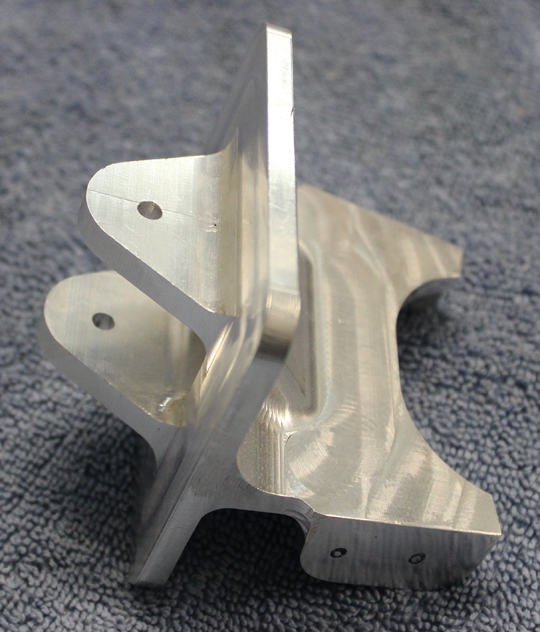

Aileron Hinges

Fitting the ailerons to the XP-82’s wings is proceeding smoothly. This required the re-manufacture of new aileron hinge fittings on the four ailerons – the Twin Mustang has four ailerons, while the P-51 has just two – and all new hinge points that mount on the wings. Reilly’s team also had to machine the new gap seal extrusions that are on the upper and lower skins on the trailing edges of the aileron bays. Also, both of the outboard flap hinges are now complete. The engineers are fitting them on each wing.

The two aileron actuating forks are also now complete, and the last remaining items the team is waiting on for aileron controls are the four cable sectors, with two mounted in each wing. The sectors are the control wheels holding the aileron cables that move the ailerons up and down.

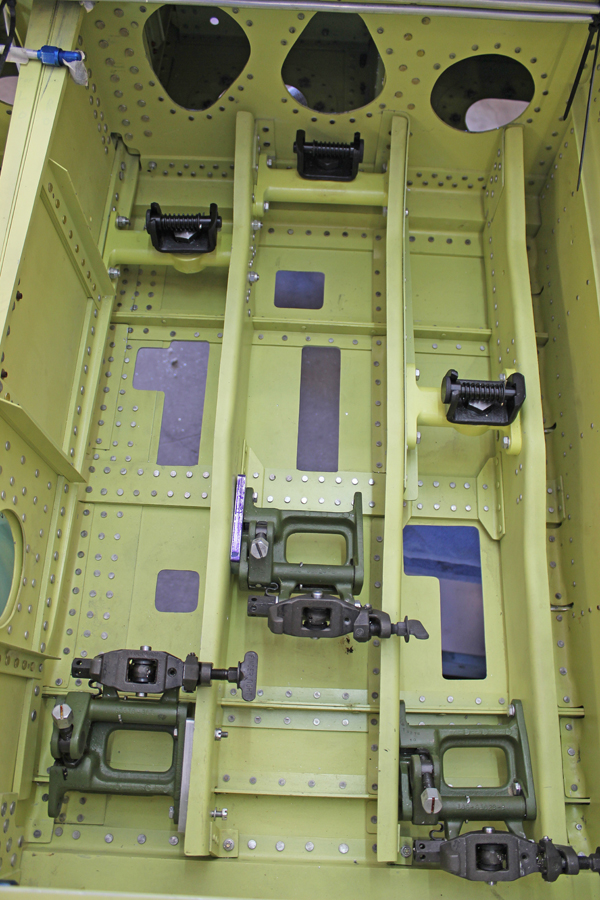

Gun Mounts All twelve gun mounts are now installed.

And that’s all for this month. Many thanks again to Tom Reilly for the update! You can learn more about the project on their blog HERE. Please be sure to check back with WarbirdsNews in early December for the next installation following the XP-82′s road to recovery!

Please click HERE for some of our previous updates.

Thanks for the information of this restoration project.

Also thanks to Tom Reilly and his co -workers for the beautiful work they have done so far.

I `ve met Tom in his Restoration Museum way back in 2002 / 2003 on a vacation when he was working on the B-17 later known as ” Liberty Belle”.

Heinz

Germany

wow tom, she is looking great ! keep on pushing guys can’t wait to see it done.