WarbirdsNews has received the latest XP-82 Twin Mustang restoration update from Tom Reilly at his workshop in Douglas, Georgia, and we thought you would all be pleased to see the latest progress!

Since the project is coming very close to completion, there are fewer and fewer major accomplishments that can be photographed. Therefore project updates will now come every two or three months following this edition.

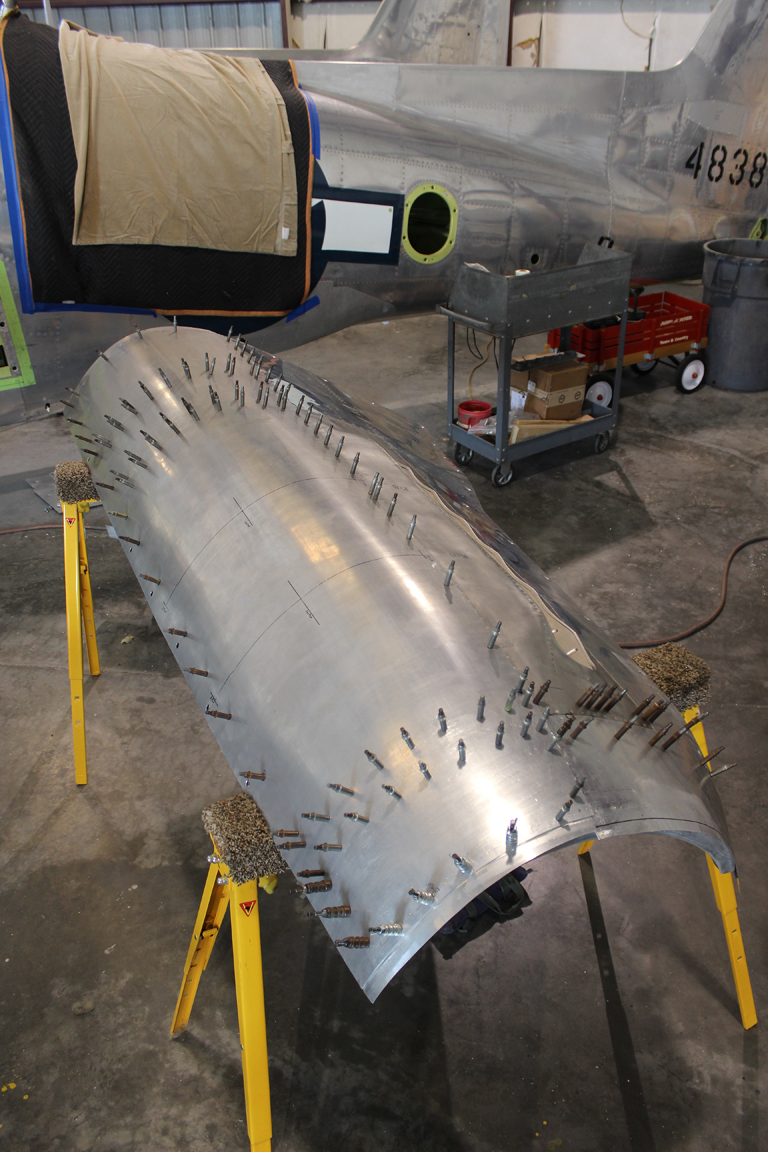

Top Engine Cowlings

Casey Hill, one of two English wheel subcontract wizards working on the project, came down for three days to help on the fairings. Tom Reilly pointed out the non-fitting top right-hand engine cowl to him and asked if he could do anything with it. It took him and Paul a day, and the two of them had it fitting perfectly. The team should have this left-hand top cowl completed within the next two weeks.

Fuselage Fairings

All of the outboard fuselage-to-wing fairings, from leading edge to trailing edge, are now complete. The team finished the final seam welding of the two outboard forward fairings this past week. Only the two lower halves for the inboard side of each fuselage-to-center-section fairing still need work.

Paul, the project’s lead sheet metal team member, has done a wonderful job by learning these English wheel and Yoder hammer sheet metal techniques, with the help from Rick Reeves, the XP-82’s other English wheel subcontract wizard. These have been very difficult pieces to form, but they have come out beautifully. In one more week, Paul will have the two bottom halves completed, awaiting seam welding. Then all of the XP-82’s fairings will be done.

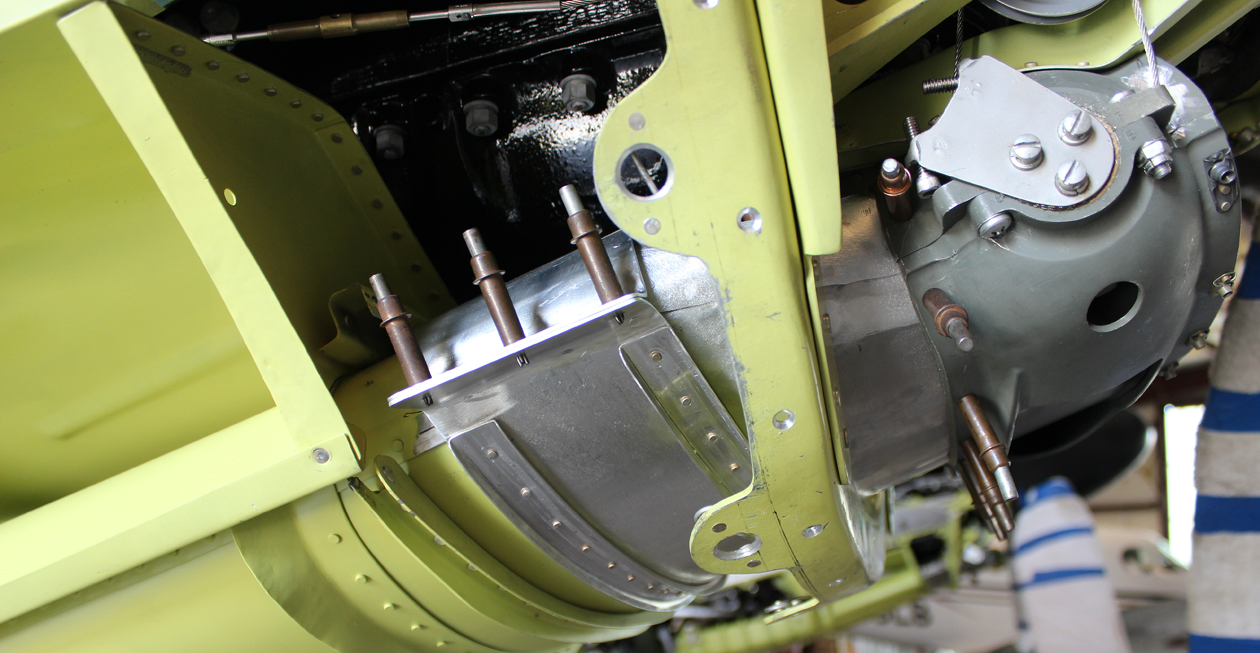

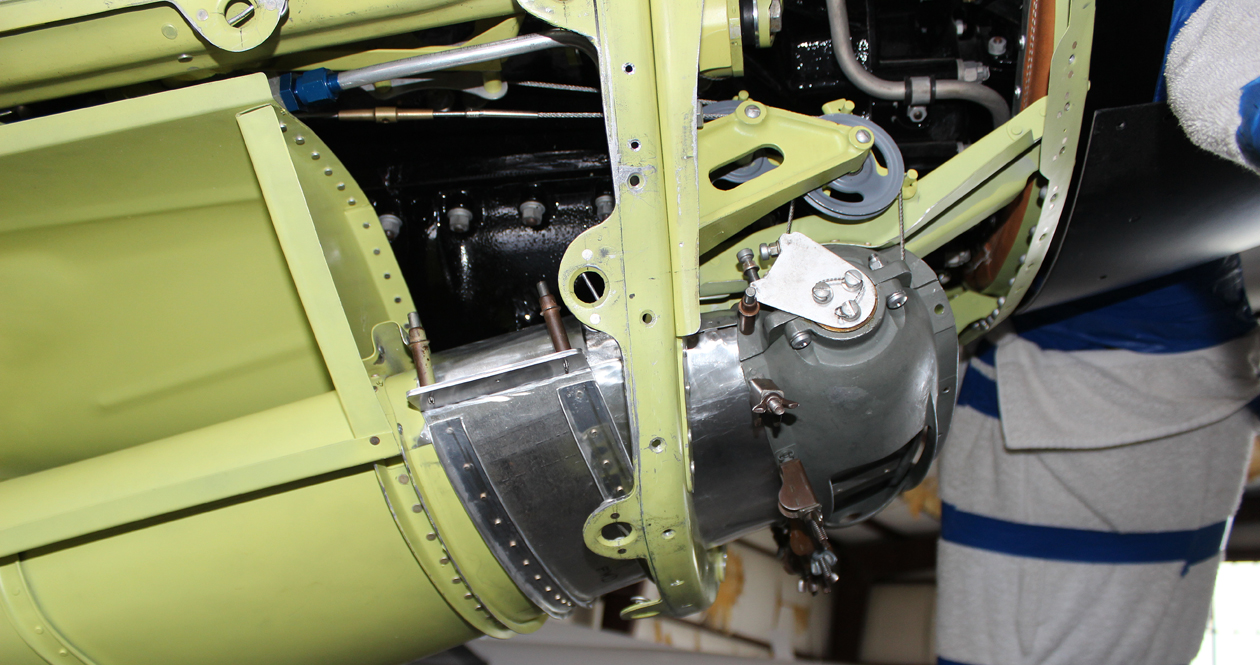

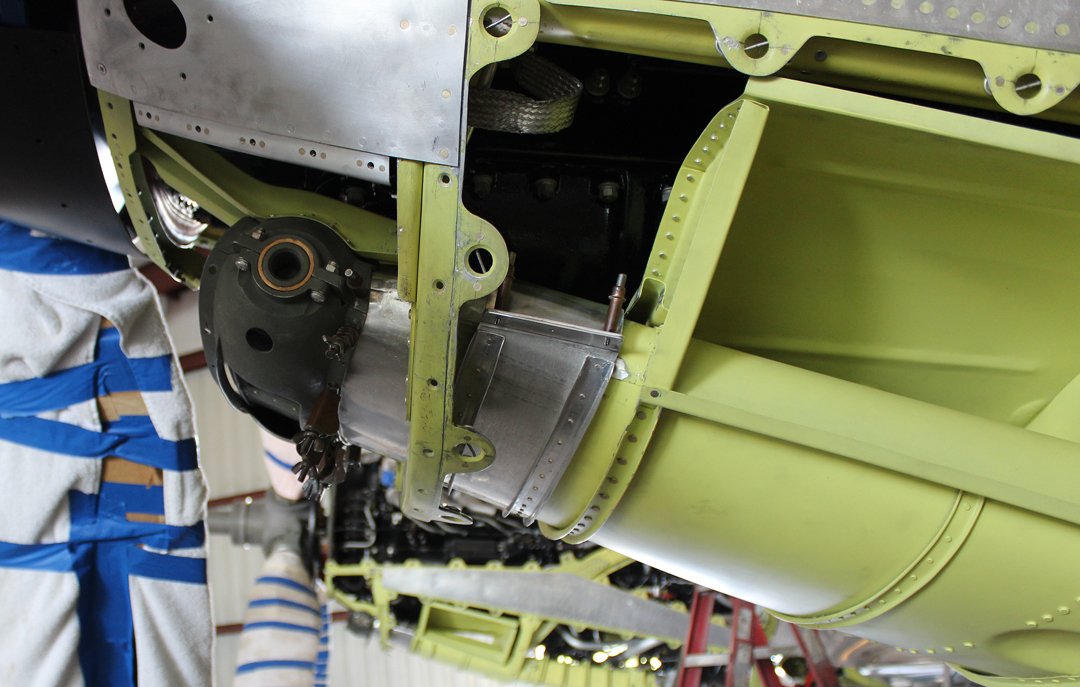

Lower Chin Cowl to Air Induction Trunk Adapters

Randall and Paiden have accomplished in two weeks what Tom Reilly expected would take at least a month: forming the two adapters that join the chin cowls to the air induction trunks as well as the adapter covers to rubber seal these two removable joints. The parts have extremely complex compound curves, which is what makes them so difficult to replicate by hand, but they are now almost ready for final installation. The only remaining thing to do is to install the rubber for the seals (presently on order).

Electrical

Two team members have been completing and checking out each electrical system, one circuit at a time. Every circuit is now proven, except for one wire on one coolant door motor, two rotating beacon resistors, and the entire up/down landing gear circuit. Within the next two weeks Tom Reilly expects to have the remainder of the electrical system completed.

Exhaust Fairings

When Tom Reilly collected the XP-82 from Walt Soplata’s farm, he found only two of the four exhaust fairings required. These secondary stainless steel exhaust fairings only fit the P-51 H Mustang and the first 22 Merlin-powered P-82s. The restoration team has scoured the earth, and surrounding planets, for a spare pair of these exhaust fairings, but none could be found. There are only three H-model Mustangs still flying, and their owners have no clue where extra fairings could be sourced.

Remanufacture of these fairings is very difficult in part because of the complex shape, but also due to the heavy gauge (.050″) of the sheet stock required and the very sharp-edged detail around each exhaust port. Thus the project has had to have to have a pair of aluminum male and female press dies (four) machined to form the replacement fairings. The team has sent one of these two mirror image exhaust fairings to a subcontract machine shop to have it 3D printed, as the computer can easily flip the orientation of the virtual part to create its mirror for 3D printing.

Avionics Package (Garmin)

The Garmin radio package has arrived and the team will begin installation sometime in July.

Man (and woman) hours spent on the XP-82 restoration to date

Tom Reilly states that his team of workers, subcontractors and volunteers, etc. has put over 173,000 hours of labor into the XP-82’s restoration over the past nine years. In contrast, North America Aviation’s engineering and fabrication teams put 1,462,190 hours into the design and manufacture of the first XP-82 up to and including its first flight. That aircraft was 44-83887, the very same Twin Mustang which Reilly and his team have been working so hard to bring back to life…

And that is all for this month’s report.

Many thanks again to Tom Reilly for this update. You can learn more about the project on their blog HERE. Although we are not exactly sure when the next formal update will come, please be sure to check back with WarbirdsNews in a couple of months for the next installment in the story following the XP-82′s road to recovery!

Any idea when this beautiful aircraft will make its first flight?

The plan is to fly it before the end of the year.

95% done, 95% to go. Stunning work being done and I really wish I lived closer to see it in person.

No amount of compliments would be sufficient to thank Tom and every single person involved in this mammoth task. The complexity of the project is astounding. All I can say is that Warbird enthusiasts around the globe (and surrounding planets) will be rejoicing once that ship takes to the air again. Keep up the great work, there’s light at the end of the tunnel!

For God’s sake..don’t bend it.!!