by Richard Mallory Allnutt

Over the past few years, AirCorps Aviation, based in Bemidji, Minnesota has developed an enviable reputation for world-class warbird restorations. This includes combat veteran P-51D Mustangs 44-63675 Sierra Sue II and 44-63864 Twilight Tear, among others. They also recently completed the restoration of the Commemorative Air Force’s P-51C known as Tuskegee Airmen.

AirCorps Aviation is much more than a restoration shop though, having entered several niche markets with exceptional products. This would include their online warbird archive, AirCorps Library, which provides a nearly complete catalog of high resolution drawings for several dozen, mostly American WWII-era military aircraft. For a very reasonable annual fee that any warbird enthusiast could afford, you get access to literally hundreds of thousands of vintage drawings and aircraft manuals in a highly efficient, searchable database. Then there is AirCorps Art, which provides accurate detail artwork from the smallest cockpit decal, to a complete set of warbird markings. And this is nothing compared to their subsidiary, Aeroscan and its retro-engineering capabilities for replicating old parts. By 3D laser scanning an original component, they are able to create a solid model for CAD refabrication. This state of the art technology produces highly accurate results compared to traditional methods saving both time and money.

But we are here today to discuss their ongoing warbird restoration projects. Currently, they are working on P-51C Mustang 43-24907 and a rare, razorback combat veteran P-47D Thunderbolt 42-27609. We will focus on the Mustang in this particular article, with a follow-up on the Thunderbolt in the coming days, after which we will provide regular updates in the same manner we have for Tom Reilly’s XP-82 Twin Mustang restoration project.

The P-51C is almost as rare as the razorback Thunderbolt. Only a handful of high-back Mustangs survived to become warbirds. With the rise in value of WWII aircraft though, once financially prohibitive restorations have become viable and early-model Mustangs have made a resurgence in recent years with several taking flight over the past decade. When completed, this rare example will join the Texas Flying Legends Museum fleet of warbirds dedicated to honoring past generations and inspiring leaders of tomorrow. The museums prior relationship with the legendary Don Lopez made the decision easy to paint her in colors representing the P-51 he named Lope’s Hope 3rd.

Lopez became an ace flying P-40s and P-51s in the China Burma India Theatre with the 23rd FG, the Army Air Corps unit which absorbed the American Volunteer Group’s ‘Flying Tigers’. Late in the war, Lopez returned to the USA, serving as a test pilot at Eglin AFB in Florida, where he flew many of America’s early jet fighters. Following an undergraduate degree in aeronautics at the Air Force Institute of Technology, he completed the masters program at Caltech, one of the world’s premier engineering schools. Apollo 8 commander, Frank Borman, was a fellow classmate and regarded him as a brilliant, unflappable engineer. Lopez went on to help establish the nascent aeronautical engineering program at the newly founded US Air Force Academy, and following retirement from the US Air Force, worked on NASA’s Apollo/Saturn V program as well as the Skylab orbital space laboratory. Lopez also became a key figure in establishing the Smithsonian’s National Air & Space Museum on the mall in Washington, DC. He served as its deputy director from the early 1970s until his death in 2008. Having met with Lopez on numerous occasions during his later life, the author can personally attest to his also being one of life’s truly great people. Soft spoken and understated, he was a man of deep intelligence, and a gentleman in every way. For a closer look at his life, please do read the Smithsonian Air & Space Magazine tribute to him HERE.

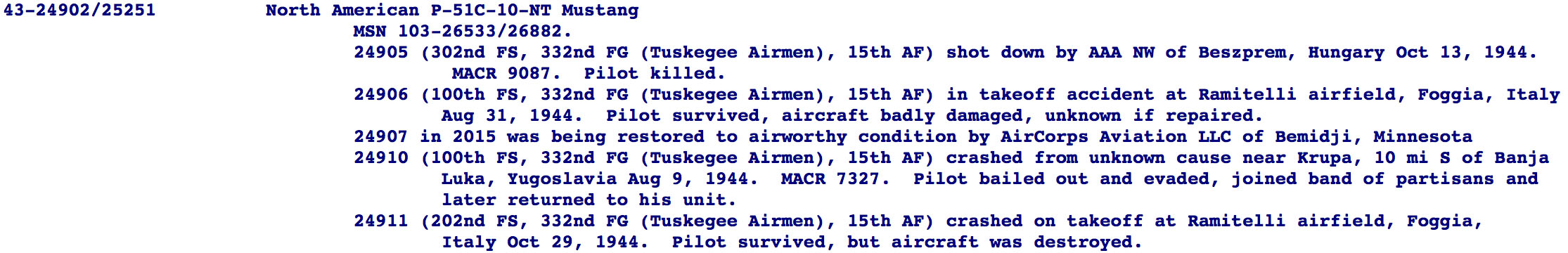

There is very little public information regarding the history of P-51C Mustang 43-24907. North American built this Mustang at their Dallas, Texas plant as construction number 103-26538. She apparently spent the war Stateside in the training role, but that is where the trail runs dry. Interestingly, Mustangs 43-24905, 24906, 24910 and 24911… just before and just after 24907 on the production line… served with the Tuskegee Airmen in Italy during WWII, so it would be interesting to know more details about this Mustang should they ever come to light.

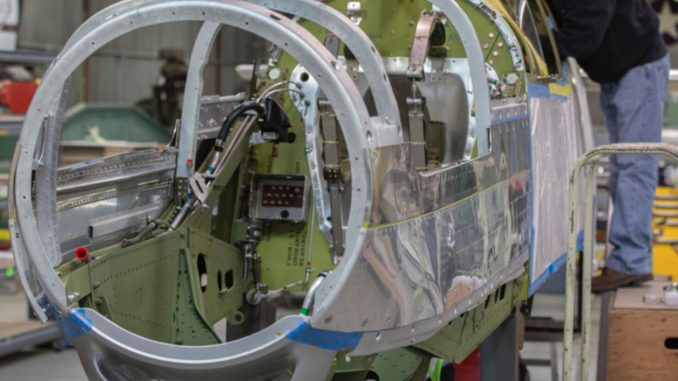

43-24907 Mustang first appeared on the US civil registry a few years ago, and AirCorps Aviation have had her under restoration since about 2014. From the looks of things, this is a down-to-the-last-rivet restoration with mostly new material. AirCorps Aviation have made rapid progress. We will now show you a brief recap of some of the major work up to now, followed by the most recent restoration report written by AirCorps’s historian, Chuck Cravens.

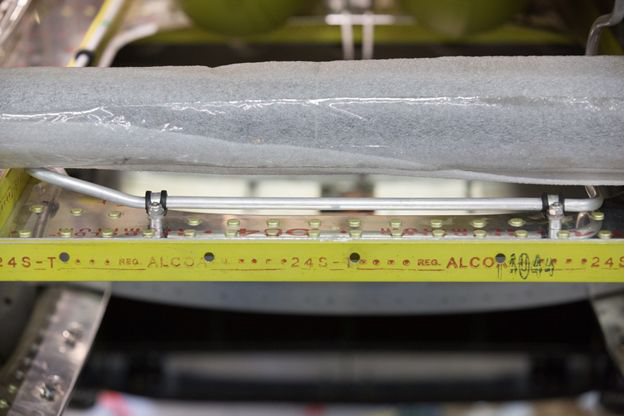

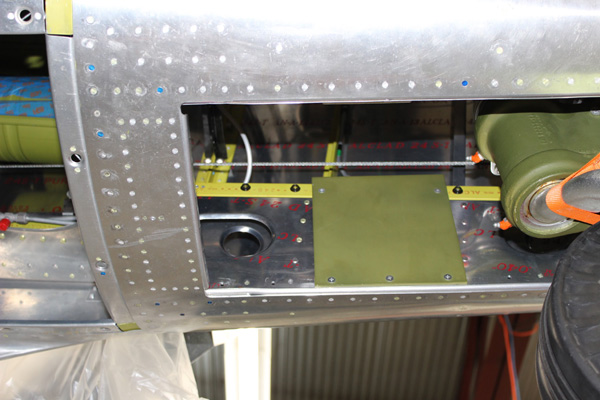

It’s not just the big stuff that’s important though, it’s all of the thousands of tiny details that matter in modern restorations too. One benefit of this level of detail is that you know if the smallest concerns receive intense scrutiny with regards to accuracy, such as the correct labeling of a hydraulic line, or an inspection stamp… things that almost no one will ever see… then the more essential elements will also be well taken care of too. This is the sort of excellence that AirCorps Aviation is known for.

And now for the February/March, 2017 update by Chuck Cravens….

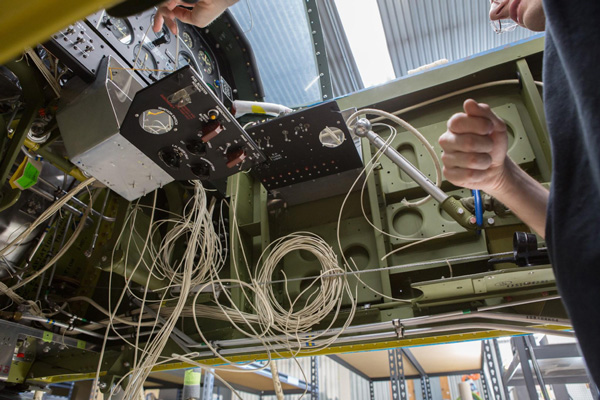

Wiring

The wire used for this restoration is identical to that used for one of AirCorps Aviation’s previous Mustang, Sierra Sue II. Both Mustangs were actually produced the same year, even though the serial numbers begin one year apart. The wiring is described as follows in Chuck Craven’s book on that restoration, Combat Vet P-51, the History of Sierra Sue II, World War Two Survivor:

Properly restoring the wiring in the airframe required duplicating wire used in 1944. The wire used then was insulated with black rubber and wound with cotton string. It was then lacquered and a logo applied. Like anything else, the current generation of available wiring is differently made and labeled. To be as true as possible to 1944, wire with black silicon insulation was custom-made by Allied Wire and cable of Pewaukee, Wisconsin. Ordinary rubber insulation is no longer allowed by FAA speci cations. The custom wire was then wrapped with cotton string like the original stuff by Narragansett Reproductions of Wood River Junction, Rhode Island.

Eric Trueblood at AirCorps Aviation researched the logo right down to the exact font used back then. He located a WWII-vintage Kingsley wire stamping machine, complete with several cases containing different sizes of the correct period type. Different sizes were used on different wire gauges.

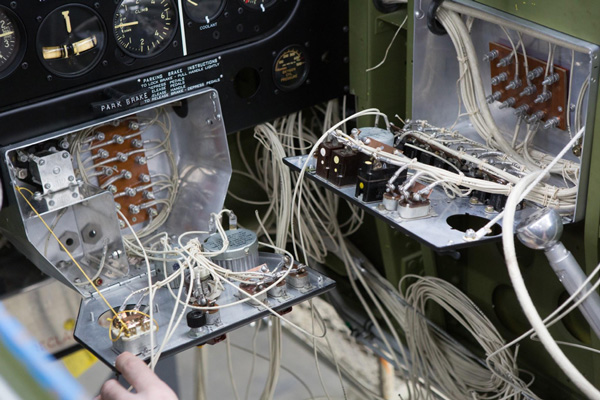

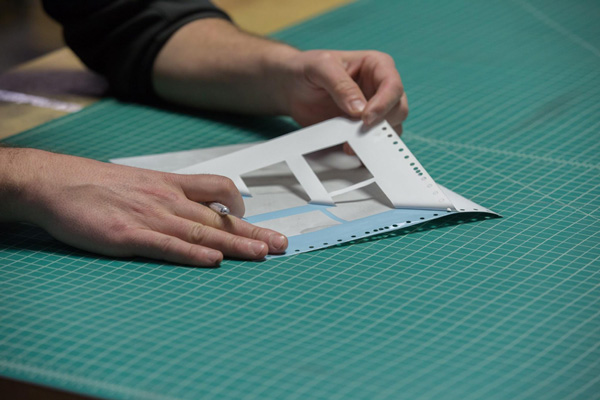

The various electrical components need art and graphics work to be accurate. The following set of photographs show the creation of a vinyl mask for properly painting the circuit breaker box cover.

Close in you can see how exacting this work can be when creatings small lines of print labels. Max is removing the vinyl from the area of a tiny letter. (photo via AirCorps Aviation)

In this case it says “RH FLOUR.” And the word “LIGHT” will be unmasked as well. It stands for “right hand fluorescent light” and is a label on the circuit breaker box cover on the right side of the cockpit. It identifies a rheostat that controls the intensity of ultraviolet cockpit interior lighting.

Landing Gear

You can see the rudder control cable alongside and above the large tail wheel casting. The two small orange projections from the green casting are Zerk fittings painted orange. North American did this to help crewmen find the fittings and to help avoid missing individual grease fittings as the P-51s were serviced in the field.

The main gear are actually the second set AirCorps have overhauled for Lope’s Hope 3rd. The first set were pressed into service when Little Horse, a P-51D also owned by Texas Flying Legends Museum, was being serviced at AirCorps. Inspection showed a crack in the pivot shaft and some wear issues. Little Horse flew out with nicely restored gear that day and left the ones removed from her at AirCorps’ hangar.

Since P-51C and D model main gear are interchangeable and both Mustangs have the same owner, AirCorps Aviation began restoring the former Little Horse gear for Lope’s Hope 3rd.

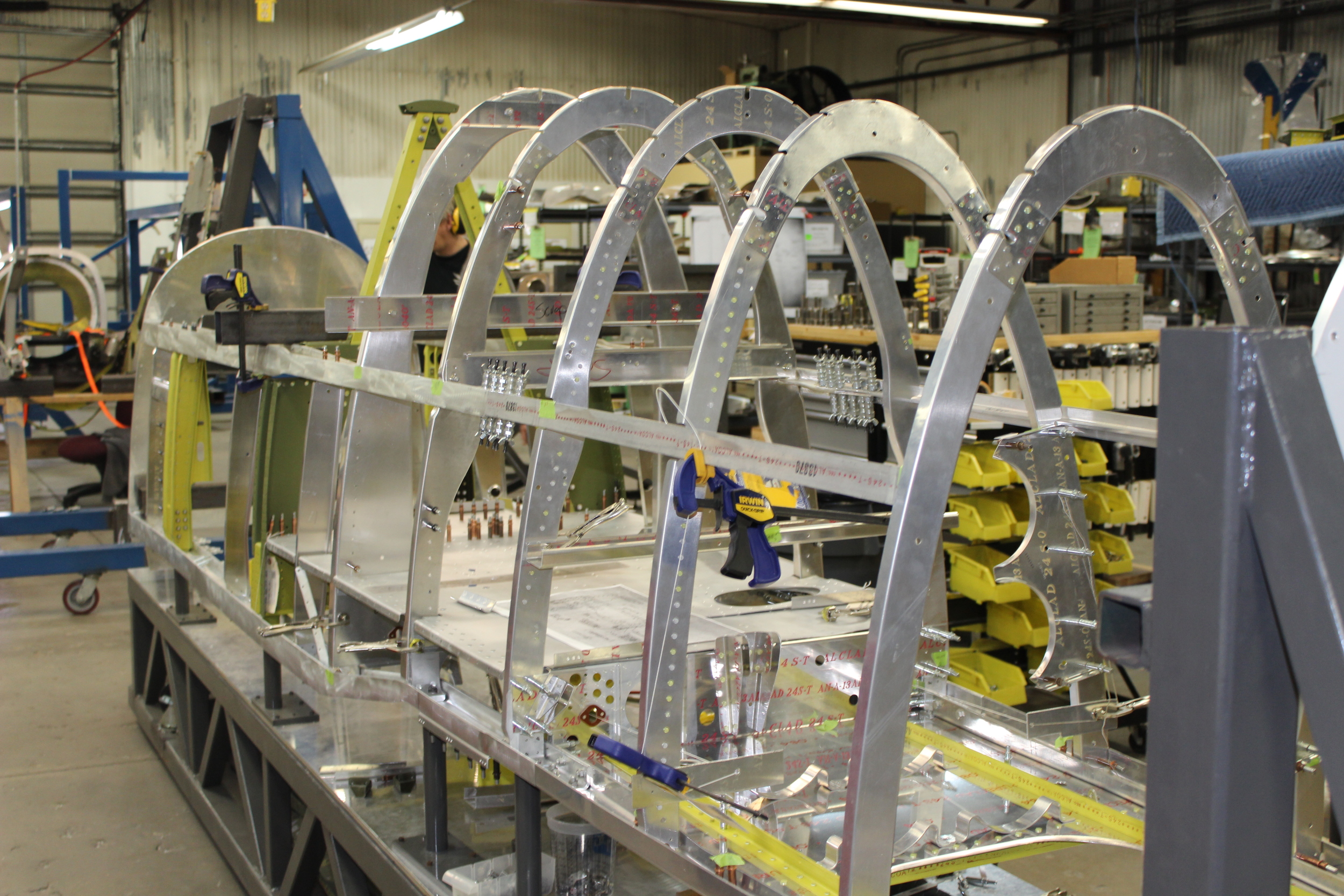

Wings

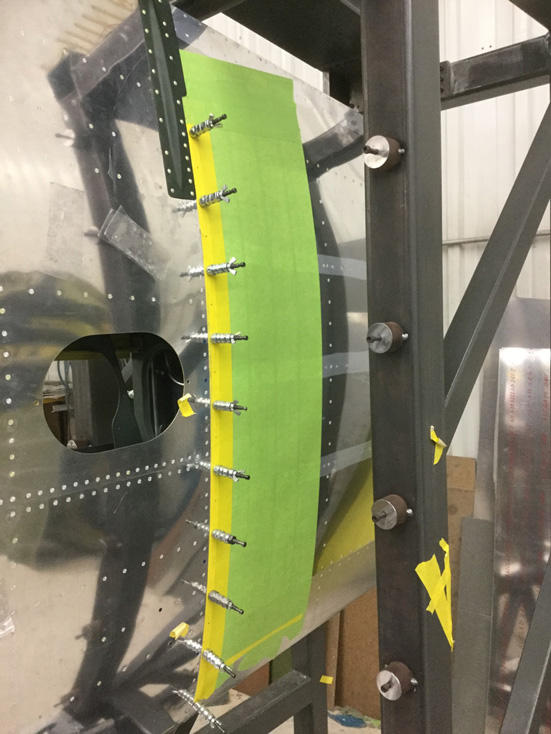

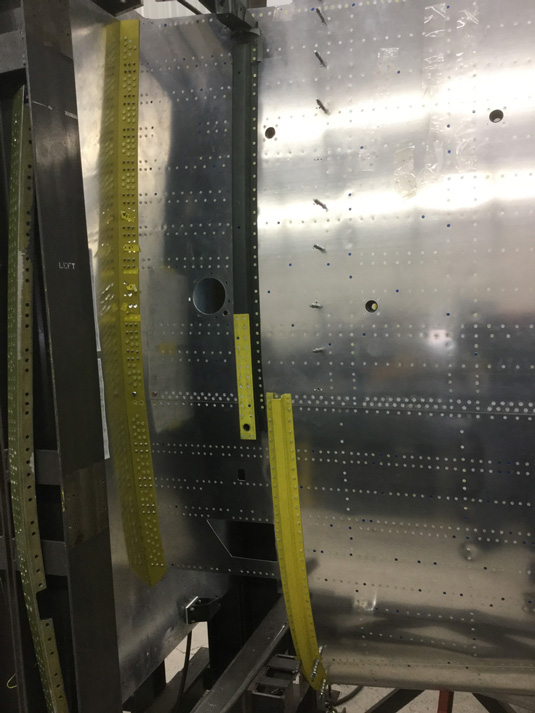

The wings for Lope’s Hope 3rd are nearing completion at Odegaard Wings. The Kindred North Dakota based warbird shop, started by the late and dearly missed Bob Odegaard, is currently filled with P-51 wings, engine mounts, landing gear doors, and Corsair aft fuselage sections.

The wing assembly parts remaining to be finished are: Station 0 rib assembly, the spade doors, and the gun bay ribs installation. When completed, the wings will be removed from the jig and the two halves bolted together. The flaps, ailerons and wing tips will then be fitted.

Once those tasks are completed, the joined wings will be shipped by truck to AirCorps and mated with the fuselage.

And that’s all for this month, please be sure to check back in May for the next installment courtesy of AirCorps Aviation. We wish to thank AirCorps Aviation and Chuck Cravens for their help in providing this article and the accompanying photographs! We will be posting a similar story about the P-47D they have under restoration in the coming week, so watch this space!

Be the first to comment

Graphic Design, Branding and Aviation Art